What is steel fiber?

A fine steel wire of a certain length and diameter added to enhance the performance of concrete. Guangya produces high-performance steel fiber with its own brand. It introduces production line from South Korea and uses water-soluble adhesive to gather bundles wholeheartedly. We call it:

The cold drawn end is glued with row shaped steel fiber.

This kind of fiber is evenly distributed in mortar or concrete to form a new type of multiphase composite material. Generally, the diameter is 0.5-1.0mm, and the length is 30-60mm. When the ratio of length to diameter is 30-100, these steel fibers can effectively improve the tensile, flexural, impact and fatigue resistance of concrete, and make the concrete have good ductility. At the same time, the two ends of the steel fiber are provided with special-shaped anchorage ends to enhance the grip force with the concrete. The anchorage end effectively transmits and distributes the stress when the concrete deforms, which is a micro crack that dissolves into micro scattered cracks.

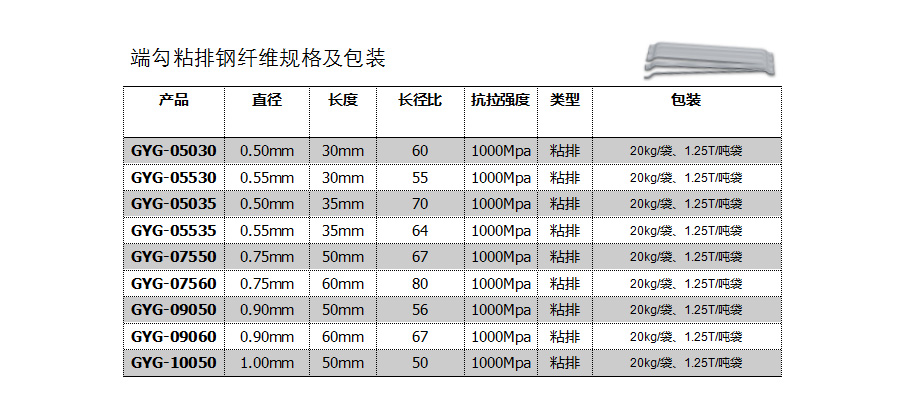

Specification of steel fiber for end hook bonding:

Compared with steel mesh, the advantages of SFRC are:

1. It can better control the curing shrinkage and increase the joint spacing;

2. Due to the uniform distribution of fibers, the structural section is uniformly strengthened within its thickness.

3. There is no need to cut or lay the mesh, thus saving the construction time and cost;

4. It is not necessary to cover the net surface with protective layer, so as to reduce the thickness of concrete.

•Application of steel fiber concrete in Tunnel Engineering:

Temporary lining

1. Improve the toughness;

2. Reduce shrinkage cracks;

3. Improve the safety and do not need to do manual welding mesh;

4. Reduce the damage caused by the accidental collapse or failure of the vault;

5. Reduce the thickness of jet lining;

6. Shorten the construction time of tunnel lining.

Permanent support

When there is only a little tensile stress in concrete or no need to use traditional reinforcement, SFRC can be used in permanent support engineering, which has the following advantages:

1. There is no need for steel bar buried depth, which reduces the thickness of sprayed lining;

2. Reduce the damage caused by the accidental collapse or failure of the vault;

3. Reduce shrinkage cracks;

4. Reduce the permeability;

5. Improve safety.

Operation and advantages (comparison between stick discharge and loose wire):

1. The steel fiber is directly added to the belt, and the whole row of steel fiber as a whole is evenly distributed in the concrete corner.

2. The water-soluble adhesive begins to dissolve in a row of steel fibers in the premise of dispersion, and then disperses in each corner of the monofilament fiber again, showing the perspective of the concrete in the fiber network, which plays an integral role in strengthening.

3. Compared with monofilament fiber, bonded steel fiber will not be bound to ensure that the fiber in concrete will not agglomerate and distribute evenly.

Bonded steel fibers are loose hooked end fibers that are bonded together in rows. The great difference between loose fiber and glued fiber is that the former is easy to block, while the latter is easy to disperse evenly. Due to its excellent tensile strength, bending shear strength, high toughness, cracking resistance, impact resistance and fatigue resistance, it is widely used in construction, road, bridge, tunnel, airport runway, water conservancy engineering, prefabrication, military engineering, blasting corrosion-resistant structure, etc.